In newspaper and magazine production, pagination primarily involves numbering and positioning editorial and advertising content as pages. It also enables the production artist to group pages, such as knowing where to add sections or supplements while working within a printer's printing plate and sheet arrangement to support print efficiency and costs.

To start, we need to work backwards. The number of pages in a publication is determined by the printing company's printing plates and the large flat sheets of paper (litho sheet-fed printing) or a large roll (web-offset printing) on which the pages will be printed.

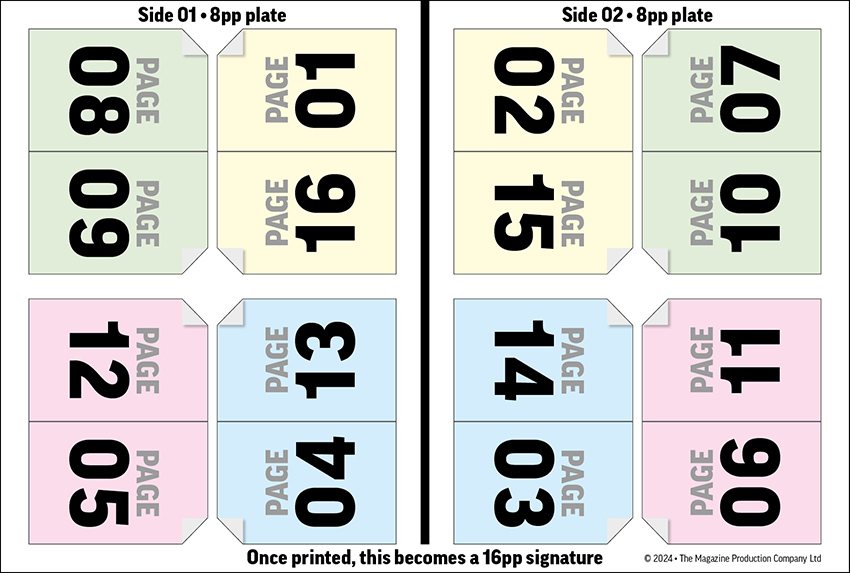

Printing plates, usually made from aluminium sheets, transfer the pages' inked image to the paper. Depending on the page size and the plates' size, each printing plate may generally contain 8, 16, or 32 printed pages (pp). The full-colour print process uses cyan, magenta, yellow and black (CMYK). One printing plate is used for each colour. We refer to a group of CMYK plates as a 'set of plates' or a 'colour set'.

Small printing presses can print 8pp in one single pass, ideal for low-run, small-paginated magazines. Larger sheet-fed printing presses print 16pp in a single pass, more suited to typical mid-paginated low- to mid-quantity print runs. Longer paginated publications with higher quantities generally require a web offset printing press, which can print 32pp in a single pass.

Here's a video showing how web offset printing works.

As a rule of thumb, we will prepare pages working to the nearest 4pp, 8pp, 16pp or 32pp, knowing there will be no issues sending pages off to print, especially if magazines are self-covered. Self-covered magazines mean the cover is printed on the same stock paper as the text, such as 32pp, 48pp, and 64pp. However, if a cover is printed on thicker paper, which may also have a lamination or UV varnish added to the front and back cover, we will add a '4pp' to the specification. We then refer to the publication's pagination with text pages and a cover as 32+4pp (32pp text and 4pp cover), 48+4pp (48pp text and 4pp cover) or 64pp+4pp (64pp text and 4pp cover) as examples.

Before you start an issue, what should you know?

When we produce a magazine, the first question we ask is the pagination — how many pages will the issue contain? This is because the publisher would have pre-arranged and agreed on the specification, pagination, quantity, specification, mailing information, cost and dates before starting the issue.

This information is usually shared well ahead of time with the editor so they can formulate their content and advertising sales to sell sufficient advertising space. Combined, we can build a flatplan to gain a snap-shot overview of where content can be paginated.

Business-to-business magazines (B2B) typically sit around 64pp text plus 4pp cover. Depending on the quantity and the printing press size, the text pagination could comprise eight sets of 8pp plates, four sets of 16pp plates, or two sets of 32pp plates. Consumer titles are usually around 160+4pp, comprising ten sets of 16pp plates or five sets of 32pp plates. Covers are printed separately. The text and the cover come together at the binding stage.

If the magazine needs to increase its pagination, we try to add the number of pages to match another set of plates, whether that may be 8pp, 16pp, or 32pp. We're mindful of optimising the cost of printing.

What happens if the final pagination is different to what you've planned?

The content must be adjusted to what is required by the printer. We know how many pages we are working towards from the outset and ensure all content is accommodated. If any content runs under or over the predetermined pagination, we then work on a contingency of adjusting copy and images to suit or introduce another feature already sidelined for such eventuality, sell last-minute advertising at a discount, donate space to charities, or include 'house adverts' to help fill space.

How does prepress ensure pages appear in the correct order?

Once a magazine is approved for printing, the next step is prepress, which is critical in magazine production as this is the point at which pages are imposed. Alongside technical artwork checks and accepting the correct pagination, the prepress software strategically arranges/imposes magazine pages, which are then imaged collectively onto printing plates. When printed double-sided, the imposed arrangement of grouping pages becomes signatures. Each signature is the number of pages printed on both sides of a sheet, typically 8pp, 16pp, 32pp, or even 64pp. Ultimately, this would ensure that when the sheets have been printed, signatures are folded, collated, bound and trimmed, pages will appear in the correct paginated order and orientation within the final magazine.

How does pagination work with digital issues?

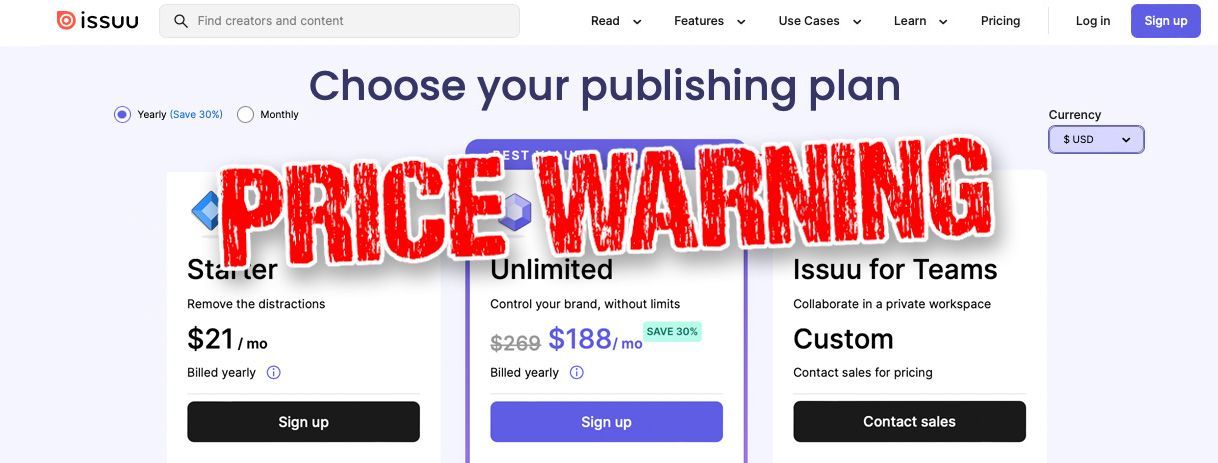

As the publication is not being printed, you can publish any number of pages or pagination length. With many page-turning solutions available, preparing pages as double-page spreads is advisable. However, we always exercise best practice by working to the nearest pagination set of fours just in case the digital issue ever needs to be printed in the future by you, your advertisers or readers.

Understanding pagination, sets of plates, imposition, and signatures can help you optimise your print efficiency.

Want to learn more about magazine production? Explore more for a wealth of resources with magazine production and publishing!

#magazineproduction #printproduction #prepress #pagination #imposition #printsignatures #graphicdesign #printing

The post 'What is pagination? The art of compiling your content for print success' appeared first on

The Magazine Production Company.

Click here to go back to the main articles page.

Share this content!

Read more of our articles