Working with black in print isn’t as black or white as you may think. As a print designer, there are three variants of blacks. Dean Cook peers into the depths of the black to explain when and where each should be applied.

Believe it or not, there are three main types of black available to us in commercial printing. You have the standard black, a heavy black and a registration black. On your screen, each looks identical, but the results are very different in print.

Standard blacks

100% Black (K) is mainly used for black text. Technically this standard black is set in InDesign (and other programs) to overprint backgrounds to avoid ink misregistration when the document is printed. However, applying a standard black to large areas, such as a solid background in an advert, it becomes apparent that just 100% black is weak. So what can you do to deepen the black further?

Heavy blacks

Increasing other colour values of cyan, yellow and magenta aids density making the black a deeper, richer black. However, we often see the same mistake when designers ramp up these three colour values to 100% to match the black (K). Increasing all colour values to 100% causes problems once the artwork is on the printing press and often when it’s too late to rectify.

Firstly, using 100% of all four colours uses an awful lot of ink; therefore, the print-minder would need to slow the press down to ensure the ink is evenly applied and avoid any ink misregistration. The job will also take longer to dry before the job can be finished, resulting in delayed delivery.

Over-use of ink can also increase the risk of scuff marks when the document is finished. In addition, it can ripple the paper making it more challenging to complete the document at the binding stage. Another common issue is that thin white/reversed out type used within the artwork will ‘fill in’ as the ink spreads once it is applied to the paper making the text difficult to read. The simple rule is never to use 100% of all colours to solid backgrounds.

So what is the correct colour values to gain a nice heavy black without disrupting the print and finishing process?

I’ve always used the colour values of 30% cyan, 30% magenta, 30% yellow, and 100% black. This particular colour value will avoid white text and thin white lines filling in, even if there is slight misregistration while on the press. Printing can still be run at the usual speed allowing ink to dry quickly and sufficiently before finishing, so the job remains on schedule. More importantly, you won’t be disappointed with the results.

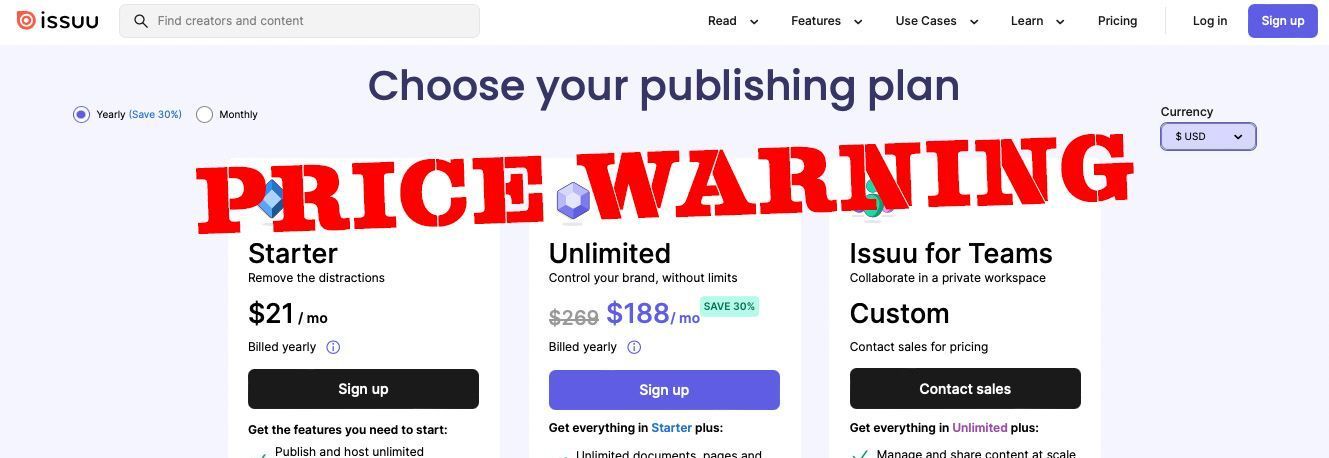

In the image above, you can see the artwork on the left side shows the text has filled in caused by the overuse of colours. The artwork on the right uses 30% of CMY and 100% K; it is dense, but more importantly, the text has far better clarity.

Registration Blacks

Finally, there is registration black which does carry 100% of all colour values. So, if designers shouldn’t use 100% CMYK in print artwork, why is it there?

This colour value specifically applies to printers marks (crop, fold, trim, etc.) that sit outside the trim edge. Because 100% of each colour is used, the print minder uses this to align the plates and gain density readings. Printers’ marks also act as marks for the finishing team so they can precisely trim the paper. Designers can also add additional finishing features, such as fold marks.

As a rule of thumb: Standard 100% K is for text only; Heavy Black (30% C, 30% M, 30% Y, 100% K) to get nice solids; and 100% of all CMYK colours is a registration black and should only apply to printer’s marks.

The post 'Using heavy blacks in artwork for printing' appeared first on

The Magazine Production Company.

Click here to go back to the main articles page.

Share this content!

Read more of our articles